Primesol & Ergo System is a leading heat exchanger manufacturers in Pune and also prominent suppliers and exporters of heat exchanger in Pune 2025. We possess a team of experts who apply tested solutions and design to enhance productivity and effectiveness of the resources. We are specialized in providing innovative, affordable, and reliable solutions to our customers for our future development. We specialize in large industry segments like chemicals, pharma, and food processing. We expand through a network of dedicated engineers with an emphasis on operational efficiency.

Being as heat exchanger suppliers in Pune, the energy conserved when waste heat generated in one process is utilized and used to warm up another, significantly reducing the cost of operation while leaving the environment free of toxic pollutants. From regulating critical temperature in delicate drug reactions to conserving energy in power plants, heat exchangers are the solution. Heat exchanger exporters in Pune are designed to provide maximum surface area for maximum heat transfer with minimal pressure drop for efficient and effective operation.

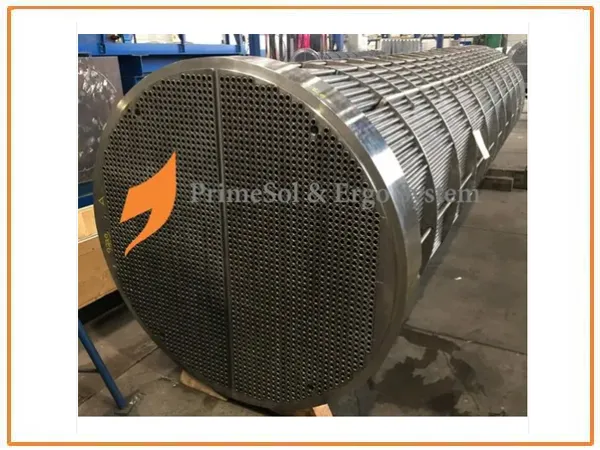

Heat exchanger is a device for heat exchange from one fluid to another fluid. It facilitates effective thermal energy transfer between two or more mediums that may be made up of liquid, gas, or a combination of the two without the mediums getting into contact.

Being as outstanding heat exchanger manufacturers in Pune, different types are modified as per requirement which given as follow.

We have added below a technical sheet of heat exchanger in Pune that provides more technical information such as:

| Heat Exchanger | Short Advanced Technical Detail |

| Heat Duty | Total heat transferred; e.g., 100 kW to 500 MW+ |

| U-value (Efficiency) | Overall heat transfer coefficient; e.g., 50–20,000 W/m²·°C |

| Pressure Rating | Design pressure; e.g., Full Vacuum to 1400 bar+ |

| Temperature Range | Design temp; e.g., -196°C to 1200°C+ |

| Materials | SS, Ti, Ni alloys, Ceramics; chosen for corrosion/temp resistance |

| Pressure Drop | Max allowable pressure loss; optimized for energy |

| Thermal Expansion Mgmt. | Expansion joints, floating heads, FEA for stress |

| Fluid Compatibility | Material resistance to process fluids (corrosion, erosion) |

| Mechanical Design | ASME code, vibration/fatigue analysis |

| Maintenance | Ease of cleaning/inspection; CIP capability |

| Software | HTRI, Aspen EDR for design/optimization |

| Material | Stainless Steel |

| Capacity | 200 to 20000 Ltr |

| Fluid Quantity | 12.507 kg/s |

| Test Pressure | 6 bar |

| Heat Exchanged | 4300 kW |

| Usage/Application | Pharmaceutical Industry |

| Brand | Primesol |

| Primary Exchanger Material | Steel |

| Size | Customize |

| Inlet Temperature | Positive Temperature |

| Outlet Temperature | Positive Temperature |

| Country of Origin | Made in Pune |

| Brand | Primesol |

| Design Standards | TEMA (R, C, B), ASME BPVC Sec VIII, API 660 |

| Heat Transfer Area | Customizable, from few m² to thousands m² |

| Pressure Rating | Shell up to 300 bar; Tube up to 1400 bar |

| Temperature Range | -100°C to 700°C+ |

| Materials | CS, SS (304, 316, Duplex), Ti, Hastelloy; often clad |

| Baffle Design | Segmental, Disc/Doughnut, Rod; optimized spacing & cut |

| Tube Sheet Design | Fixed, Floating Head, U-Tube (for thermal expansion/cleaning) |

| Fouling Factor | 0.000043 m²K/W for water |

| Nozzle Design | ρv² limits, Impingement plates for protection |

| Vibration Analysis | Critical to prevent tube failure; advanced software used |

| Heat Transfer Area | 0.1 m² to 2400 m² in single unit |

| U-value (Efficiency) | 3,000 to 9,000 W/m²·°C |

| Pressure Rating | Up to 100 bar+ |

| Temperature Range | -196°C to 400°C |

| Plate Materials | SS (304, 316), Titanium, Hastelloy, SMO 254 |

| Gasket Materials | NBR, EPDM, Viton, PTFE |

| Plate Patterns | Herringbone, Dimple, Free Flow |

| Port Connections | DN25 to DN500; various types (flanged, hygienic) |

| Channel Gap | 2–12mm (standard to wide gap) |

| Operating Temp. Range | Common: 200–600°C; Extreme: up to 1200°C+ |

| Materials | High-temp SS (310S, 321), Nickel Alloys (Inconel, Hastelloy), Ceramics (SiC) |

| Thermal Stress Mgmt. | Expansion joints, floating heads, FEA for stress analysis |

| Heat Transfer | Convection & significant radiation; radiation shielding |

| Fouling/Erosion | Design for cleanability (soot blowers), hard materials/coatings |

| Pressure Integrity | Thicker walls, stress relieving, adherence to ASME/TEMA |

| Heat Recovery | High effectiveness via counter-current flow, pinch analysis |

| Safety/Instrumentation | High-temp sensors, appropriate pressure relief |

| Primary Application | Gas-to-liquid/gas heat transfer |

| Design Standards | API 661, ASME BPVC |

| Fin Type & Geometry | Extruded, L-Foot, G-Fin; 2–11 FPI, 0.375–1.5" fin height |

| Materials | Tubes: CS, SS, Cu, Ti; Fins: Al, Cu, SS |

| Temperature Range | Up to 600°C |

| Pressure Rating | Tubes up to 200 bar+ |

| Fan Config & Drive | Forced/Induced Draft; VFD-controlled electric motors |

| Tube Arrangement | Staggered (high HTC) or In-Line (low pressure drop) |

| Airside Pressure Drop | Critical for fan power, optimized design |

| Heat Duty | Designed for specific kW/BTU/hr; achieving required approach temp |

Serve as outstanding heat exchanger suppliers in Pune, different benefits are there as per requirement which is given below:

As heat exchanger exporters in Pune, it is applied in different industrial uses as per requirement which is given below.

As Primesol & Ergo System is the premier heat exchanger manufacturers in Pune and prominent suppliers and exporters of heat exchanger in Pune is an engineering device for effective heat transfer of thermal energy between two or more fluids at different temperatures without fluid mixing. There is a transfer of heat through a solid separator in the most widely encountered type of conduction and convection principles. Fluid flow paths are optimized, and heat exchanger machine manufacturers in Pune, thus leading to maximum thermal performance as well as minimized energy loss. For utilization, and maintenance of equipment operational integrity, thereby contributing substantially to energy conservation and optimization of process. Contact us for more details.

Ans: Heat exchangers serve as tools for transferring heat from one medium to another.

Ans: Heat flows from a hotter fluid to a colder fluid through a separating surface.

Ans: Shell-and-tube, plate, double pipe, and finned-tube are the most common.

Ans: It maximizes heat transfer efficiency by maintaining a larger average temperature difference between fluids.